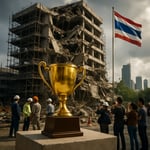

As the month approaches its end, rescue teams remain determined to reach the ground level of the fallen State Audit Office (SAO) building, a herculean task made all the more pressing with each passing day. This spectacular collapse, resulting from the infamous March 28 earthquake, has already claimed the lives of 53 individuals, with an additional 41 souls still tragically unaccounted for. As the capital city, Bangkok, finds itself in the throes of sorrow, the urgency to recover the missing is palpable.

In the latest turn of events, a concerted crackdown by the Bangkok Metropolitan Administration has led to the confiscation of substandard steel, valued at a staggering 11.5 million baht. This inferior material was seized from a plant nestled in the bustling Chon Buri province. Adding an international dimension to the scandal, the operation’s spotlight also fell on six Chinese nationals. These workers, employed by Chon Buri Special Steel Group, were found to be laboring without the necessary permits and now face imminent deportation.

Chon Buri Special Steel Group, with its deep roots in Chinese investments, notably shares its Chon Buri premises with its investor, Teng Feng Steel. The inspection squad, led by the indefatigable Thitipat Chotidechachainan, unearthed the continuing use of the notorious induction furnace—a choice that undeniably compromises product quality. Consequently, more than 115,000 reinforcing bars, collectively weighing over 582 tonnes, found themselves intercepted by the authorities.

This dramatic raid follows an earlier February intervention where substandard steel, amounting to a hefty 23 million baht, was similarly seized, resulting in the firm’s operational license being revoked in the aftermath. Meanwhile, the seismic ripple effects of the SAO collapse continue to unfold. The culpable steel, allegedly manufactured by Xin Ke Yuan Steel Company Limited, was also forged using an induction furnace. The ensuing investigations have only magnified the controversy surrounding the project’s steel quality.

Spokesperson Pongpol Yodmuangcharoen from the Industry Ministry divulged that rigorous testing conducted by the Iron and Steel Institute of Thailand on steel samples from the SAO site confirmed their subpar 20-millimetre diameter. Such findings are crucial pieces in the Department of Special Investigation’s larger inquiry into the tragedy’s genesis. Pongpol remarked that this calamity adds another layer to Xin Ke Yuan Steel’s existing legal woes, following their prior steel test failures on March 31.

The industry’s ongoing battle against the “zero-dollar industry” is nowhere near its conclusion. The narrative, dominated by substandard steel, keeps spiraling into new depths. Over 384 million baht worth of material has borne the brunt of the crackdown across the past seven months, all courtesy of the much-maligned induction furnace fabrication method.

As rescue personnel maneuvers the ruins of the SAO, the drive remains unyielding—to dismantle the debris mountain that overshadows the erstwhile ground floor. With hopes of discovering trapped individuals still flickering, this mission is as much about closure as it is about accountability. While the tragedy underscores the perils of cutting corners in construction, it also emboldens the spirit of perseverance, as Bangkok trudges through its most somber of chapters.

I can’t believe we’re still facing these issues with substandard construction materials! How many more buildings need to collapse before proper regulations are enforced?

Honestly, it all comes down to corruption. Everyone’s pocketing money instead of ensuring safety. It’s disgusting.

Kevin, you’re spot on. We engineers have been highlighting this for years. It’s not just corruption, but lack of proper inspections too.

While corruption is a huge issue, isn’t it also on consumers to demand better standards? We should all be more vigilant about the buildings we use.

Sophia, that’s a fair point, but I think it’s unreasonable to expect every consumer to have the technical knowledge to assess building integrity.

Maybe we should start building everything out of Lego bricks instead. At least then we’ll know they fit together!

This is a complete disaster. Just deporting the illegal workers isn’t enough. What about those running the operation?

Exactly, Raj. The executives who ignored safety protocols should face serious charges. It’s too easy for them to escape accountability.

It’s tragic that many lives are still unaccounted for. My heart goes out to the rescue teams working endlessly.

It must be so tough on them. But I think the focus should also shift to preventing future disasters by improving regulations.

True, Peter. Prevention is key. I just hope the authorities learn from this disaster.

With every raid, more substandard steel is found. It’s hard to trust any new construction now.

There’s actually a lot of good builders out there. This scandal just makes it harder for everyone in the industry.

Ben, I hope you’re right. I wish there were a quick and reliable way to identify the good ones.

I don’t get why they keep using induction furnaces if they’re problematic. Surely there’s a more reliable method out there?

This just shows how systemic problems have deeply rooted in the industry. Reform is long overdue.

Larry, maybe what we need is more international collaboration. Other countries have tackled similar issues successfully.

Oh please, Eli. There are forces at play here way beyond what we see on the surface. This is just the tip of the iceberg.

Can someone explain why it took this tragedy to prompt action? Shouldn’t have this been addressed a long time ago?

Because governments react instead of proact. They always wait for something bad to happen before changing anything.

That’s unfortunately true, Julie. It’s a pattern we’ve seen time and again.

I think it’s interesting how the international dimension shows up here. It’s never just one country’s problem anymore.