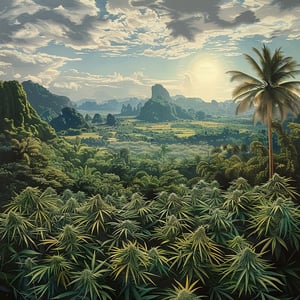

Tucked away in the lush landscapes of Chaiyaphum province, particularly in the quaint tambon Ban Tan of the Bamnet Narong district, there’s a vibrant scene of local ingenuity where residents have turned their attention to harnessing the saline-rich soil to extract and sell salt. While this salt trade thrives, a unique collaboration is quietly unfolding, promising to drive agricultural progress and sustainability in the region. The King Mongkut’s University of Technology Thonburi (KMUTT) has partnered with the Royal Irrigation Department (RID) in an ambitious project utilizing bio-cement to combat the vexing issue of soil salinity in Northeastern Thailand.

The protagonist in this tale of innovation is bio-cement, a cutting-edge material devised by the Smart Biomaterials and Technology Research Group at KMUTT. Thidarat Bunsri, a dedicated researcher from the group, explains that bio-cement is crafted from microbial-induced calcium carbonate—an organic compound that is the brainchild of microbes derived from the residue of fermented fish bones, an abundant byproduct of industrial fish sauce production. Now, that’s what you call putting waste to good use!

This saline-resistant material, armed with the magic of geopolymer technology, showcases its prowess by managing to keep rainwater from escaping while also ensuring that the infamous ground salt stays put where it belongs—underground. According to RID’s civil engineer, Peerawat Phuengpaphat, the challenges of saline soil and sandy earth have long impeded healthy agriculture in these parts. The region’s ancestral history as a primordial sea left a mark—an underlying abundance of rock salt mingled with sandy soil, which had always been a tricky match for storing rainwater. Imagine the woes of a region where the rains just breeze through the thirsty soil and leave premature salt crystal growth in their wake during the dry season—it’s a farmer’s tale of woe, indeed.

But enter bio-cement, armed with all the good stuff: silicates and alumina-rich gangues, a zesty microbial solution, and egg shells to nourish the microbial workforce. This miracle material has a knack for resisting salt erosion, and what’s more, it can self-heal from micro-cracks by generating calcium carbonate crystals. The robust efforts in this bio-cement venture haven’t gone unnoticed, with key support from industry giants like Charoen Pokphand Foods and Akara Resources lending their backing.

Nature’s rewards are set to reveal themselves at the Irrigation Experiment Station No 3 (Huay Ban Yang) in Muang district of Nakhon Ratchasima, where a pilot is underway. Within the bounds of a rice field, bio-cement sheets measuring a hearty 75 centimeters square and a sturdy 8.5 centimeters thick are being put to the test in field lysimeters. Their mission? To observe and analyze water evaporation rates amidst plants and soil while working the magic of bio-cement, slowing the absorption rate, and preventing the encroachment of salt onto the water. The evaluative eyes of researchers will keenly follow the cycle of rice growth over four months, examining regular updates on the material’s self-repairing capabilities and salt fighting stance.

If the trial yields the anticipated victories, Ms. Thidarat and her adept team are optimistic about expanding the formula of bio-cement into the realm of 3D printing, with bold visions of constructing artificial reefs or bioconcrete to preserve underground water supplies. This project shines not only as a groundbreaking stride in agricultural innovation but also as a beacon of hope for environmental sustainability. The whispers of imminent expansion into other regions are growing louder with every lab result and field test.

Indeed, the alliance between KMUTT and RID, backed by industry supporters, showcases a marvel of ingenuity that aims to foster an eco-friendly future while tackling the formidable challenges presented by mother nature herself. And, who knows? Soon enough, other far-reaching areas may bask in the fruits of this remarkable venture. In the lush orchards of innovation, opportunity seeds are sprouting—eager to blossom and redefine agriculture’s dance with the environment.

This bio-cement sounds like a miracle solution! But isn’t there a risk of it having unintended environmental impacts?

Interesting point, Joe. While innovations like this are promising, we must rigorously assess their environmental footprint before full-scale implementation.

I don’t see the issue, Joe. The project’s goal is to improve sustainability, which seems like it’s addressing potential environmental concerns. We need solutions, not more problems!

Sustainability is important, but we can’t ignore any possible side effects. Proper testing is a must.

Joe’s right. Balancing innovation with caution is necessary, especially in agriculture where ecosystems can be fragile.

Absolutely love this idea! If this works, it could revolutionize how we deal with saline soil worldwide.

Not to mention the economic boost for local farmers once soil salinity issues are mitigated.

True, but scaling this technology globally might present challenges. Different soils might react differently.

That’s a valid point, Jay. Perhaps further research could address those variances.

Why not just stop farming in these regions and move agriculture elsewhere? Seems like a waste of resources.

That’s easier said than done, Bobby. Some regions rely heavily on agriculture for their economies and livelihoods.

Moving agriculture isn’t always an option. Plus, solving the salinity problem is a step towards sustainability.

Fair enough, but isn’t technology-driven agriculture expensive for these communities?

I’m curious about the cost-effectiveness of bio-cement compared to traditional soil treatments.

Great question, Karen. The initial investment might be high, but long-term savings from improved soil health could outweigh costs.

The use of waste like fish bones is clever, but isn’t there a limit to how much can be sourced sustainably?

Good point, Jack! This might work well in regions with ample fish industry waste but could face limits elsewhere.

If bio-cement really self-heals, why hasn’t it been adopted already in other areas facing salinity issues?

Development and proper testing take time, Cathy. Plus, introducing new tech at a large scale can be quite challenging.

This project is another example of how humans adapt to their environment—amazing!

While this sounds promising, we need more info on how it affects farmer incomes and economic structures.

Exactly, Debbie. Integrating new tech into existing systems is crucial for success, especially in economically sensitive areas.

Bio-cement might be just what other arid regions need. Let’s hope they share findings globally.

Agreed! Sharing data could open up new agricultural solutions worldwide.

Thanks, globalgreen! Hopefully, international collaborations will help improve and expand this technology.

Why haven’t governments invested more in these kinds of sustainable technologies?

Governments often wait for clear results before investing taxpayer money. It can be frustratingly slow.

That makes sense, but it feels like we’re missing out on faster progress.

Could bio-cement potentially harm the biological systems around it?

The risk might exist, Sam, but it sounds like they’re considering these factors carefully before deployment.